Roller Shutter Doors

Roller shutter doors manufactured by Centurion Doors are of tried and tested design, specifically engineered and manufactured to the requirements of the end user. Our roller shutter doors offer very good security and could be used at workshops, warehouses and shop fronts.

THE BARREL ASSEMBLY

The barrel assembly (Shaft) are spring loaded to counter balance the weight to ensure easy operation for the operator.

We have 2 types of barrels, and open shaft and a closed shaft.

The size of the springs gets determined by the square meter age of the roller shutter door as well as whether the shaft will be open or closed.

Roller shutter doors comes standard in galvanise, but we do epoxy if so required.

END-PLATES

End-plates are manufactured of 4 mm steel cut and bent at our workshop into the desired size to suite the height of the roller shutter door. The end-plates are the section of the roller shutter door that will be fixed above the opening either on concrete, steel or brickwork. This then will house the barrel to complete the top assembly of the roller shutter door.

| END-PLATE SIZE | MAXIMUM GUIDE RAIL HEIGHT |

| 300mm | 2.100m |

| 350mm | 3.600m |

| 400mm | 5.100m |

| 450mm | 5.500m |

Larger end-plates can be made to order as well as higher roller shutter doors

GUIDE RAILS

Guide rails are cold rolled galvanised steel which are roller by a roll forming machine at our workshop. Guides are 25mm x 75mm x 3mm. we also manufacture guide to 100mm and 150mm wide respectively.

SLATS

|

Centurion doors slats are 75mm wide x 0.8mm and 1mm think respectively with a deep concave design, thus the assembled curtain offers high wind resistance. We do however manufacture the following slats: Solid slats (also available in aluminium) |

|

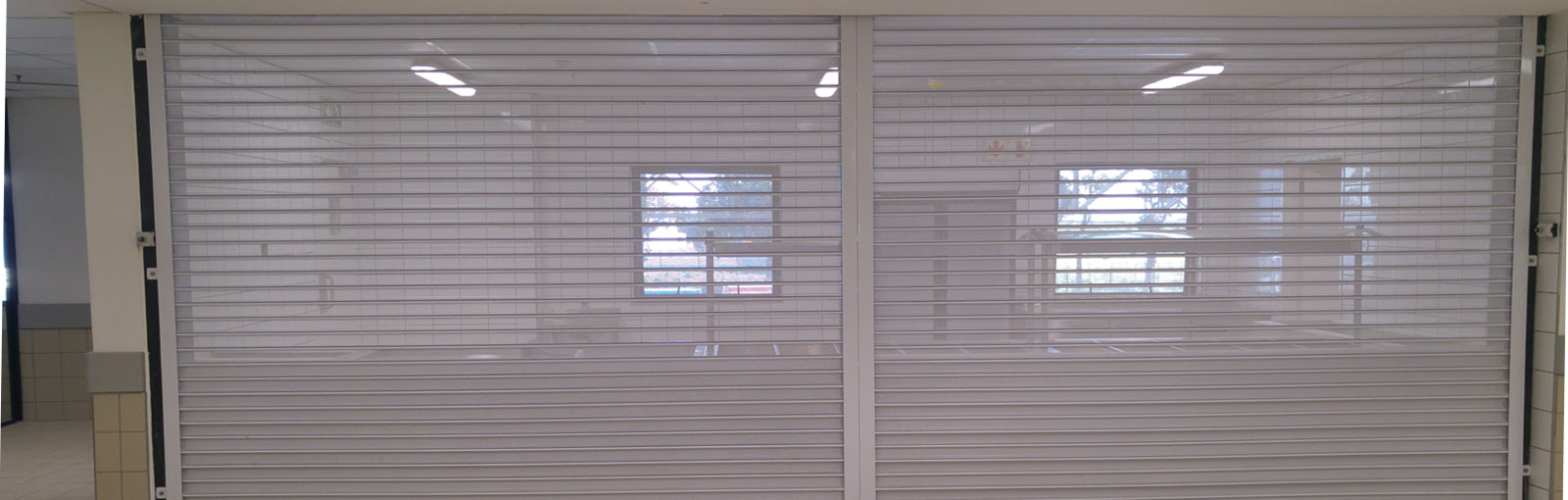

| Finestra slats (also available in aluminium) – used where airflow is required as well as for shop fronts. |  |

| Perforated slats – used where airflow is required as well as for shop fronts. |  |

|

T-SECTION (T-BAR) Out T-Sections (T-bar) are manufactured from aluminium or 40 x 40 x 5 mild steel angle iron will be hot dipped galvanised). The aluminium T-bar is to our specification and comes with an optional sponge rubber to reduce dust or water from coming in under the roller shutter door. The Galvanised steel T-bar is used by the clients request or on our fire roller shutter doors. NB: All components of a roller shutter door will, like the barrel assembly, guide rails and T-bar, will be the same in all the types of roller shutter doors. The only difference will be the type of slat. |

|

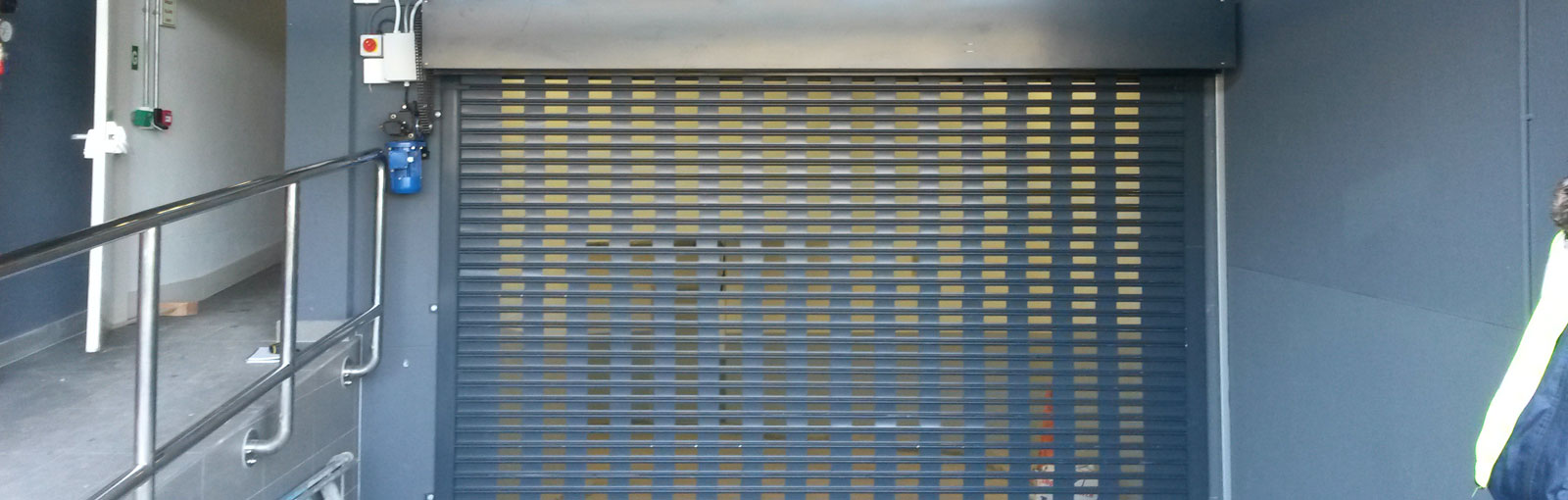

ROLLER GRILLE DOORSAs an alternative to a roller shutter door can a roller grille door be manufactures. This door Does not have any slats and the curtain assembly is from 10mm round bar pressed into a Predetermined shape and cut into lengths to suite the opening size. These rods are hot dipped galvanised. The bars are linked horizontally with (hot dipped galvanised) steel clips. When assembled and suspended the bars form a curtain with a patterned grille (as opposed to a shutter). Its robust design gives high security yet clear vision. This is ideal for shop fronts or parking garages where ventilation is required. |

|

|

OPERATING SYSTEMS

There are 4 common operating methods to a roller shutter door, namely “Push-up”, “Gear / Crank”, “Chain” and “Electrical” operated.

PUSH-UP OPERATION

These roller shutter doors operate on a push up and pull down operation. This will not be recommended for doors above 2.500m wide x 2.500m high. This is further more suitable for roller shutter doors fitted between walls where no space is allowed for a crank or other operating system.

|

GEAR / CRANK OPERATION A larger door (because of the weight of its curtain) needs mechanical assistance for its operation. This is done through a crank handle type gearbox (wall mounted at waist height) driving via a connecting steel tube to the crown wheel and pinion fixed to one end of the barrel assembly. CHAIN OPERATION A chain wheel complete with reduction gears is mounted to the end of the barrel assembly and is driven by means of a chain wheel and continues chain. This option will be relevant in the case where a crank cannot be fitted due to space on the side for the handle to operate. Will furthermore be recommended where pedestrians are walking and a crank mechanism poses a threat to pedestrians being injured wil walking by. |

|

|

ELECTRICAL OPERATION We supply and install (complete with commissioning to the main power supply from an isolator switch supplied by other). The 2 options of motors are 220V and 380V. All motors will be fitted standard with a up / down switch control box. Optional will be remote controls, key switch operation and safety beams (photocells) |

|

TECHNICAL INFORMATION